Entering the astronomical clock

The small metal door leads inside the clock to all its floors: to the calendar floor, astronomical floor, the timekeeping floor and the topmost floor with the Apostles. It is a narrow and low entrance but it is not so bad for the visitor to bow unwittingly. The entire system of the astronomical clock deserves it.

Around the tower, there were small merchants’ shops as we can

see in period paintings. They were liquidated in

1838, although the increased municipal income from the leases was

certainly welcome. The entrance to the astronomical clock lead from the

town hall chapel into the room now occupied by the Apostles. The

current entrance to the clock was built later (1882) when the entire

town hall was reconstructed and the clock was out of order during the

construction works. We must emphasize that there is quite enough

information on the original machine of the clock. The basic forged

parts have been preserved – above all, the three pointer wheels, parts

of the chiming machine and the frame structure. J. Táborský’s

description from the 16th century documents sufficiently the technical

system of the clock and performed adjustments and assumed that the

machine had not been essentially modified before the adjustments at the

end of the 15th century,

They were liquidated in

1838, although the increased municipal income from the leases was

certainly welcome. The entrance to the astronomical clock lead from the

town hall chapel into the room now occupied by the Apostles. The

current entrance to the clock was built later (1882) when the entire

town hall was reconstructed and the clock was out of order during the

construction works. We must emphasize that there is quite enough

information on the original machine of the clock. The basic forged

parts have been preserved – above all, the three pointer wheels, parts

of the chiming machine and the frame structure. J. Táborský’s

description from the 16th century documents sufficiently the technical

system of the clock and performed adjustments and assumed that the

machine had not been essentially modified before the adjustments at the

end of the 15th century,

Táborský came to

the original machine.

Individual independently winded machines are embedded in the original

forged frame. Today, the weights are controlled by electric motors and

chains with automatic winding. The weights are moving in the lower

floor, in the room beneath the calendar plate. In the times of V.

Rosický, there were still manually winded drums with ropes for

individual machines. Here we publish a period photograph of the

interior of the machine together with a lateral drawing and a

photograph of the machine before the reconstruction.

Táborský came to

the original machine.

Individual independently winded machines are embedded in the original

forged frame. Today, the weights are controlled by electric motors and

chains with automatic winding. The weights are moving in the lower

floor, in the room beneath the calendar plate. In the times of V.

Rosický, there were still manually winded drums with ropes for

individual machines. Here we publish a period photograph of the

interior of the machine together with a lateral drawing and a

photograph of the machine before the reconstruction.

The main machine

The main machine

The pointer machine or else main machine, in modern terms the going machine, controls the three pointers on the astronomical dial. It is this machine that unlocks other machines, the chiming machine with the machine of the Apostles and the control of the calendar plate. It activates them in determined intervals; this is called “releasing” and it means that the machines carry out the intended activity and mechanically lock themselves at the end. Then they wait for another impulse from the main machine. Since 1865, this machine is controlled by a separate clock machine and makes one step per minute; its function is described in detail in the chapter on Božek’s chronometer.

In the room with of these machines, there is the modern machine of the 24-hour dial, but this machine is separate and is not connected with the historical machines. More information can also be found in the dedicated chapter.

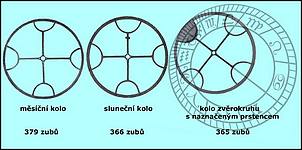

The heart of the going machine is formed by three forged tooth

wheels for the movement of the Sun, Moon and Zodiac. The Sun wheel

makes one turn per day (solar day) and it has 366 teeth. The ecliptic

wheel has 365 teeth and also makes one turn per day (sideral day), that

means that it rotates slightly faster and the difference of one tooth

causes that the difference of the cycles of the Sun and the Zodiac

equals one day. Thus the Sun passes through all the signs marked on the

Zodiac ring in the course of the year and it indicates in which sign it

is on the current day within the year.

The third forged wheel is the Moon wheel. It has 379 teeth. The Moon has its own cycle in the sky and this cycle is related to its rotation around the Earth during which all his phases pass; that makes approx. 29.1 days. It is also related to the Sun because it is the difference between their rotation speed what causes the moon phases. At full moon, the Moon is alight by the reflected light of the Sun – they are in socalled opposition; at new moon, it is not visible because it moves over the sky during the day and is outshined by the Sun. Strictly speaking, it can be seen but only when the Sun is eclipsed. při zatmění Slunce.

The movement of the Sun symbol along the Zodiac ring is unequivocally resolved by the ratio of the numbers of teeth; the Moon wheel with its 379 teeth is not in the ideal proportion to them. It cannot be because it would have to have a fractional number of teeth, which is technically impossible. Thus is the Moon symbol deviated from the reality approx. by one day per quarter of a year. Therefore it needed to be adjusted more often, which was not a problem as the adjustment of the entire machine was the main business of the clockmaster and we can say that he was at the machine every day. As Táborský wrote (1570): “The Moon cannot be fully aligned because the teeth in its wheel cannot be aligned with the teeth of the Zodiac and the movement of the Moon in the sky... When it is not aligned, you have to amend it manually…” The ratio of the teeth of individual wheels 365 : 366 : 379 was the best compromise for the rotating objects on the clock.

We can theorize with mathematicians and assume a multiple of

the number of the teeth on all the wheels, e. g. sextuple. In that

case, the number of teeth would be 2190 : 2196 : 2274. The change of

the number of teeth of the Moon wheel by one tooth would mean a

significant increase in precision; the deviation of one day would occur

in approx. eight years. However, the height of the teeth, while

maintaining the current wheel diameter (116 cm) would have to be

approx. 0,25 cm; this is a size that would be difficult even for modern

precision mechanics (calculation performed by Dr. Z. Šíma).

Furthermore, the pinions would skip the small teeth uncontrollably. So

let us put up with the number of teeth as our ancestors made them six

hundred years ago and, again, let us remind Táborský stating that “…

you must help it manually”.  The problem of the incorrectness of

the Moon’s movement was resolved during the additional repairs in 1866

(after the first inauguration, see the chapter on history); the

mechanism is described in detail by V. Rosický. The corrective

differential machine for the Moon was designed and constructed by Čeněk

V. Daněk in his manufacture; the transmission was calculated by Gustav

Schmidt, a professor at the Prague polytechnic school. Since it is

still present on the clock today, we can show it on a photograph. The

movement of the transmission is derived from the original pinion; it

returns through the tooth wheel and a new lower pinion back to the Moon

wheel like over a shunt. The Moon wheel is attached loosely to its

original axle and is driven by another wheel of the corrective machine.

This transmission is not absolutely precise either (it was not possible

to interpose larger wheels) but the deviation was considerably reduced.

The problem of the incorrectness of

the Moon’s movement was resolved during the additional repairs in 1866

(after the first inauguration, see the chapter on history); the

mechanism is described in detail by V. Rosický. The corrective

differential machine for the Moon was designed and constructed by Čeněk

V. Daněk in his manufacture; the transmission was calculated by Gustav

Schmidt, a professor at the Prague polytechnic school. Since it is

still present on the clock today, we can show it on a photograph. The

movement of the transmission is derived from the original pinion; it

returns through the tooth wheel and a new lower pinion back to the Moon

wheel like over a shunt. The Moon wheel is attached loosely to its

original axle and is driven by another wheel of the corrective machine.

This transmission is not absolutely precise either (it was not possible

to interpose larger wheels) but the deviation was considerably reduced.

All the three main forged wheels have the same diameter of 116 cm with approx. 1.2 cm high preforged and sawed teeth with triangular profile; the details of the fabrication of the wheels are presented in a separate chapter (Praise of smith craft); the accuracy of 1 millimetre was not a question in the times of smiths. From the beginning, the wheels were attached to a common axle, which meant making an axle for the Zodiac and two more hollow shafts around it. This is how three coaxial movements were transmitted from the insides of the machine to the dial, which is one of the constructional unique features of the Prague astronomical clock. Current hollow axles and the shaft are not original; they were manufactured using the technology of the 19th century. The wheels were driven by one common pinion. To be precise, let us say that there are four coaxial movements transmitted to the astronomical dial because there is the modern mechanism of the 24hour dial (see the dedicated chapter). However, this mechanism is not connected with the historical machine.

The Zodiac wheel has an asymmetrical and distinct feature:

there is a heavy lead weight on one of its beams on the perimeter; the

weight bears marks that remind the calibration of an automobile tyre.

It is due to the fact that the wheel supports the Zodiac ring on the

astronomical dial, which is attached eccentrically. The weight on the

internal wheel thus counterbalances the outside ring.

During the reconstruction in 1865, the crate became too small as the chiming machine for releasing of the Apostles and other mechanisms such as the control of releasing of the going machine from the chronometer were modified. The machine of the Apostles starts spinning for about half a minute once per hour. There are three vanes by the machine and another small one by the chronometer.

The Sun wheel bears 24 pins on one side; these are intended for the control (by string) of the releasing machine of the calendar plate on the floor underneath the main machine.

All that is necessary is to take into account the leap year

every four years and detach the control string for one day. The

calendar wheel is balanced on its axle by a weight. There are

irregularly placed pins visible on the wheel that were intended for

releasing of the movement of the 24hour dial; they are not functional

today.  The mechanism was constructed in

1865 and we describe it in detail in a dedicated chapter. The movement

of the calendar wheel, derived from the Sun wheel’s movement, was

relatively easily resoluble even at the time of the adjustments made by

Jan Růže (1490). It was probably him who wanted to establish it but it

was not realized and the plate was moved manually every day. It was

automated by Táborský in 1566, as he informs us in his Report. It was

his interest to make his own work simpler as he had to enter the

machine every day. Táborský improved the astronomical clock for twenty

years (until 1572) and handed it over to his successors as a fully

automated machine, of course within the possibilities of that time.

The mechanism was constructed in

1865 and we describe it in detail in a dedicated chapter. The movement

of the calendar wheel, derived from the Sun wheel’s movement, was

relatively easily resoluble even at the time of the adjustments made by

Jan Růže (1490). It was probably him who wanted to establish it but it

was not realized and the plate was moved manually every day. It was

automated by Táborský in 1566, as he informs us in his Report. It was

his interest to make his own work simpler as he had to enter the

machine every day. Táborský improved the astronomical clock for twenty

years (until 1572) and handed it over to his successors as a fully

automated machine, of course within the possibilities of that time.

During the repair in 1864–65, the chiming device was modified for the movement of the Apostles but this adjustment did not impact the basic structure of the clock. The entire device works as follows: upon releasing the Apostles and during their movement around two swivels (six arms on a heptagon), four movable sculptures move at the same time; the Death strikes its bell and after the defile has finished (40 seconds), the cimbalom starts to chime. The transmission to the upper floor with the Apostles is resolved by a chain wheel that protrudes from the bottom of the grate.

At the end, let us remind a machine that is no longer present

on the astronomical clock – the first clock. It was at some time in the

13th century when a mechanism for regular stepped movement – the crown

wheel – was created. The system

consists of horizontally placed, usually square bars in the shape of a

ruler with two movable weights on its arms. It rotates around a

vertical axle, which is another rod attached to it. The vertical bar

has two blades that are pushed in turn by the “crooked” teeth forged on

the side of the hoop – the crown wheel.

The wheel is

driven in a common manner by a drum with a rope and a weight. In old

clocks, the weights were usually made of stone. When swung to the

extreme positions, the crown wheel returns slightly backwards and thus

exercises a spindle and also reverse movement. The motion of the entire

system is slowed down or accelerated by shifting the two weights along

the horizontal arms. The reverse movement causes inaccuracy; the first

clocks with this system usually showed deviations up to half an hour

per day. We do not know who invented the step system with the crown

wheel, but it was the only way for wheel machines to release fluently

and slowly one tooth after another until the use of pendulum (the

principle of pendulum by Galileo Galilei, 1637, in clockmaker’s

practice Christian Huygens, 1656).

The wheel is

driven in a common manner by a drum with a rope and a weight. In old

clocks, the weights were usually made of stone. When swung to the

extreme positions, the crown wheel returns slightly backwards and thus

exercises a spindle and also reverse movement. The motion of the entire

system is slowed down or accelerated by shifting the two weights along

the horizontal arms. The reverse movement causes inaccuracy; the first

clocks with this system usually showed deviations up to half an hour

per day. We do not know who invented the step system with the crown

wheel, but it was the only way for wheel machines to release fluently

and slowly one tooth after another until the use of pendulum (the

principle of pendulum by Galileo Galilei, 1637, in clockmaker’s

practice Christian Huygens, 1656).

Clocks with the original crown wheel mechanism are rare today. Many of them were later converted to a pendulous oscillator. It is a shame that Táborský could not have known the principle of pendulum. In another chapter, we write about J. Prokeš who offered the repair of the astronomical clock in the middle of the 19th century but we do not know whether he wanted to preserve the original machine with the crown wheel or to replace it. The original clock was installed on the Prague astronomical clock until the great reconstruction in 1864–65, when it was decided to replace it with a modern chronometer by R. Božek. This machine became the main, going machine and now controls the operation of the clock. But this is another stage of the development and we deal with it in a dedicated chapter.